Attaining Superior Completed With In-Mold Decorations in Production

Wiki Article

Mastering In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Ideal Outcomes

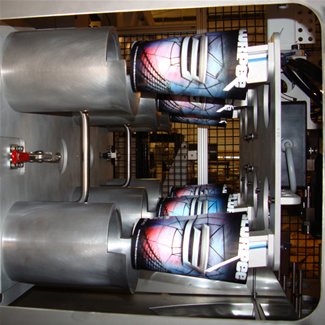

In the world of manufacturing, the art of in-mold decorations stands as a critical element of item layout and production. In-Mold Decorations. By delving right into the approaches, trends, and best methods that underpin successful in-mold design procedures, organizations can open a realm of possibilities that not only elevate the aesthetic appeal of their items however also enhance manufacturing effectiveness and strengthen customer engagement.Material Selection

Material selection is an essential facet of understanding in-mold decors, as it straight affects the high quality and longevity of the end product. When selecting materials for in-mold decorations, it is important to consider factors such as compatibility with the molding procedure, the wanted visual outcome, and the environmental problems the item will face. Polycarbonate products like abdominal muscle, polypropylene, and polycarbonate are generally made use of for in-mold designs due to their versatility and ability to attain detailed styles. These materials supply excellent moldability, making it possible for makers to create intricate shapes and patterns with precision.Additionally, the selected material needs to possess excellent adhesion residential properties to make sure that the decoration sticks firmly to the substratum during the molding procedure. Adhesion in between the decor and the product is crucial for protecting against delamination and making sure lasting aesthetic allure. Furthermore, products with high warm resistance are chosen for in-mold designs, especially for products that will certainly be revealed to elevated temperatures throughout their lifecycle. By thoroughly selecting the appropriate material for in-mold designs, manufacturers can improve the total quality and longevity of their products, meeting the expectations of both clients and end-users.

Design Development

A crucial consider progressing the area of in-mold designs is the continuous exploration and execution of style advancement methods. Design innovation plays an essential role in boosting the visual charm, performance, and overall top quality of items produced using in-mold decoration procedures. By integrating ingenious design components, makers can distinguish their products in the marketplace, draw in consumers, and remain in advance of competitors.Among the vital elements of design technology in in-mold designs is the combination of intricate patterns, appearances, and graphics that were previously challenging to attain with conventional decor techniques. Advanced technologies such as 3D printing and electronic design devices allow developers to create complicated and comprehensive layouts that can be perfectly moved onto molded components. In addition, using vibrant shades, metallic surfaces, and special results like gloss or matte structures can better raise the aesthetic charm of in-mold decorated products.

Additionally, layout innovation prolongs beyond appearances to encompass practical enhancements such as ergonomic forms, integrated functions, and personalized elements that deal with details user requirements. By welcoming design click resources advancement, manufacturers can unlock brand-new opportunities for creativity, personalization, and item distinction in the competitive landscape of in-mold decorations.

Production Effectiveness

Reliable manufacturing processes are vital for equating the innovative designs created in the area of in-mold designs into top quality completed products that meet market needs and consumer assumptions. In the world of in-mold decors, manufacturing performance includes different key facets that contribute to the general success of the production procedure.Furthermore, carrying out automation and robotics in the assembly line can substantially improve performance by enhancing repetitive jobs and minimizing the margin of error. Automation not just speeds up the manufacturing process but likewise enhances accuracy and repeatability, causing a more consistent and top quality final product. Moreover, adopting lean production concepts, such as just-in-time stock monitoring and waste reduction methods, can even more improve production effectiveness by decreasing downtime and enhancing source utilization. Generally, an all natural approach to production effectiveness is extremely important in making best use of the potential of in-mold design methods and attaining optimal lead to the competitive market landscape.

Quality Assurance Measures

What are the vital techniques for guaranteeing rigorous high quality control procedures in the realm of in-mold designs? Quality control steps are paramount in in-mold design procedures to ensure the manufacturing of remarkable and top notch finished products.Using innovative innovations such as automated assessment systems can likewise improve the high quality control process by offering accurate and trusted data for evaluation. These systems can spot flaws that might be missed out on by hand-operated examinations, therefore boosting overall product top quality and uniformity.

Routine training and development programs for staff members included in the in-mold decoration procedure can additionally add to maintaining top quality criteria. By informing staff on finest methods, high quality expectations, and the significance of interest to information, firms can promote a culture of high quality consciousness throughout the organization.

Customer Appeal

To improve the bankability of in-mold decor products, providing and useful content understanding to consumer preferences play a crucial duty in determining their charm and success. Providing personalization options such as individualized designs, shade variants, and textural components can substantially boost the appeal of in-mold decor products.

Verdict

In-mold designs offer a functional and efficient way to enhance item visual appeals. Understanding in-mold designs requires an all natural strategy that thinks about all facets of the manufacturing procedure to guarantee success.In the realm of manufacturing, the art of in-mold decors stands as an essential element of item style and production. Design technology plays a critical role in improving the aesthetic appeal, performance, and overall high quality of items produced using in-mold decoration procedures.One of the crucial facets of style advancement in in-mold decorations is the integration of detailed patterns, textures, and graphics that were formerly testing to attain with standard decor approaches.Reliable production processes are important for translating the ingenious designs created in the area of in-mold decorations right into top notch ended up products that satisfy market needs and consumer assumptions. Providing modification choices such as individualized styles, color variants, and textural elements can significantly enhance the charm of in-mold decoration items.

Report this wiki page